Xinxiang Xinli Filter Technology Co., Ltd. was established in August 2010 With a registered capital of 50.5 million yuan, the company covers an area of more than 40 mu. The main products are complete sets of process filter devices and metal sintering filter equipment. The business direction covers filtration and separation fields in petrochemical, chemical, metallurgy, pharmaceutical, water treatment, environmental protection, machinery and other industries. The specific products are: 1. Self-cleaning filtration system 2. Multi-unit filtration system 3. High temperature dust removal filtration system 4. Metal sintering filter elements 5. Metal sintering filter materials and other industrial filtration equipment and equipment.

Mr. Zhao Wenxiang, the legal representative of the company, is one of the earliest technical experts specializing in the research and development and manufacturing of metal sintering filter equipment in China, a member of the China Filtration and Separation Industry Association, and the main draftsman of the national standard for stainless steel metal woven sintered wire mesh and stainless steel metal fiber sintered felt products. He has published many papers in important journals at home and abroad and won the science and technology Progress award issued by the government. He has a number of practical technology patents and enjoys a high reputation in the industry.

More than 10 years of experience in filter and vacuum sintering research and development, as well as years of focus on cultivating a professional filter design and research and development of technical team, the company has developed rapidly in recent years. At present, it has 13 internationally advanced vacuum sintering production lines, eight welding production lines, more than 100 sets of various process equipment, process technology and quality testing system are perfect, and product quality has reached the international advanced level.

At present, the company has more than 400 employees, including 60 people with bachelor degree and 45 people with college degree or above; The registered capital increased from the initial 10.5 million RMB to 50.5 million RMB; After the expansion of the company in 2017, it covers an area of 26,640 square meters.

The company’s existing products have been applied in major projects related to the national economy and people’s livelihood, such as coal-fired boiler discharge, urban sewage treatment, high-temperature flue gas dust removal, oilfield reinjection, power plant desulfurization and denitrification, geothermal circulating water utilization, agricultural energy-saving irrigation, etc. Under the background of vigorously developing green economy and industrial energy-saving transformation, the product market prospects are very broad.

At present, the company’s modern enterprise structure and management system has been initially formed, and steadily develops under the guidance of continuous innovation, continuous improvement, integrity management and harmonious development, with good product research and development capabilities and market development capabilities.

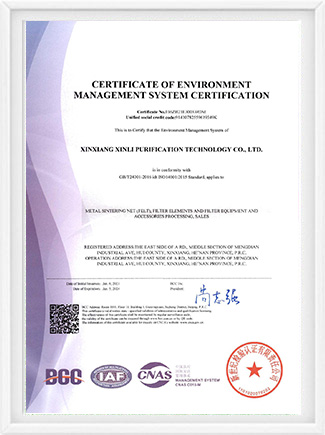

Certificate Of Environment

Management System Certification

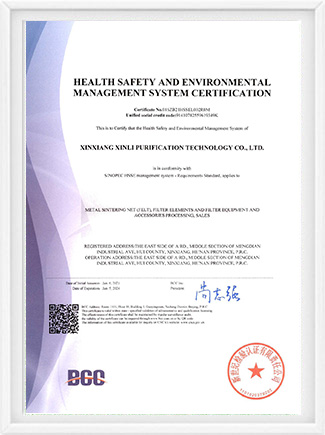

Health Safety And Environmental

Management System Certification

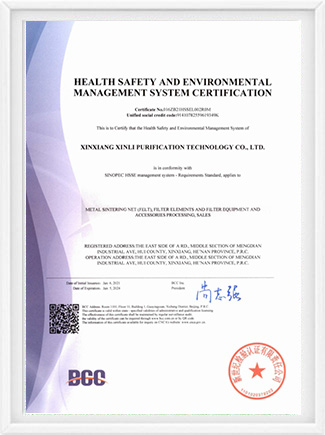

Health Safety And Environmental

Management System Certification

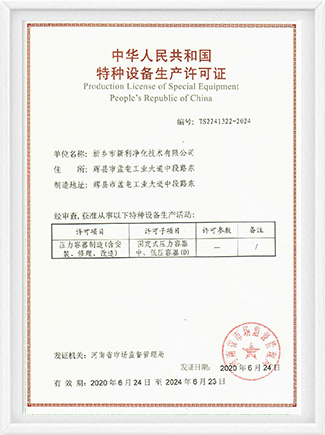

Production License of Special Equipment

People’s Republic of China

Certificate Of Environment

Management System Certification

Certificate Of Environment

Management System Certification

►Properties for raw materials: technical department set the properties requirements for needed raw materials by correlated standards.

►Selection and assessment of Suppliers: production department selects the raw material suppliers by the properties set ahead from the directory of qualified suppliers. Any new suppliers must be evaluated and assessed and thus approved if qualified. All suppliers must undergo a regular inspection.

►Stocking for production: pick test shall be executed on every batch of raw materials by quality inspectors. If passed, then accepted and stored along with qualified certificates and inspection report. Thereafter, raw materials can be applied from warehouse for processing.